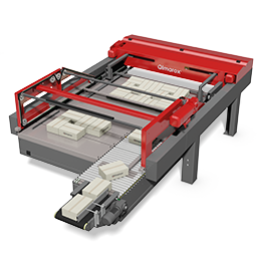

The Highrunner HR7 series Palletiser is used for handling capacities of 1,000 – 3,500 products per hour.

Palletising Layer by layer

The Highrunner HR7 is the fastest, most flexible palletiser from the Qimarox range. What is interesting is that the products are deposited on the pallet layer by layer with the Highrunner HR7. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR7 needs to make fewer movements. This saves time, which increases the capacity.

Because it’s the pallet that moves up and down with the Highrunner HR7 flexible palletiser, the rows no longer need to be moved up and down while being deposited. That saves even more time, especially with pallets that need to be stacked 1.80 metres or higher. This makes the Highrunner HR7 one of the fastest palletisers on the market.

Infeed and Outfeed of Pallets

As soon as a pallet is full, the pallet lift moves all the way down so that it can be carried away via a pallet transport system. An empty pallet can be supplied from the opposite direction at the same time.

The Highrunner HR7 can handle a wide range of products:

- boxes

- boxes with lids

- trays

- trays with foil

- buckets

- crates

- jerrycans

- etc.