Asmech Systems Ltd offer a highly effective solution to our customers for quality loop inverters for a range of industries including food, beverage and healthcare.

The primary reason customers choose us is due to our ability to integrate systems whilst utilising existing conveyor lines and machinery, usually preventing the need for customers to allocate additional funds to replace the infeed and outfeed conveyor systems.

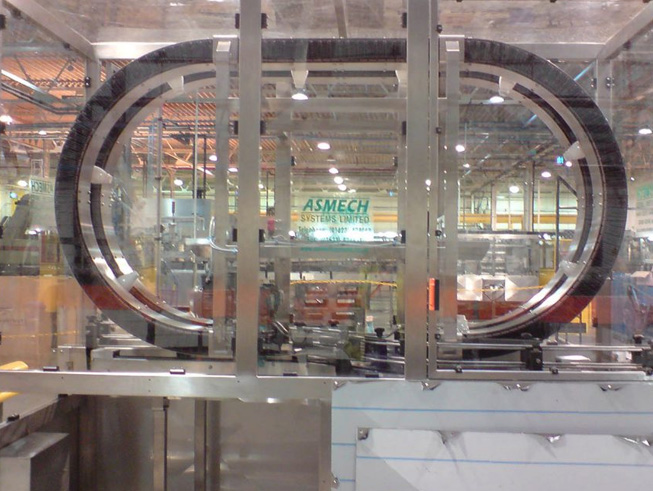

Loop inverters are primarily used to change the orientation of products for specific periods of time, ejecting debris in them before they are filled. Many clients from the dairy and beverage sectors have purchased loop inverters. These inverters are comparable to side grippers and elevators, using gripper chains to hold products. We have even designed systems that are able to turn bottles upside down to enable the coating of the bottom side of caps so they can be sterilised as part of the hot filling process.