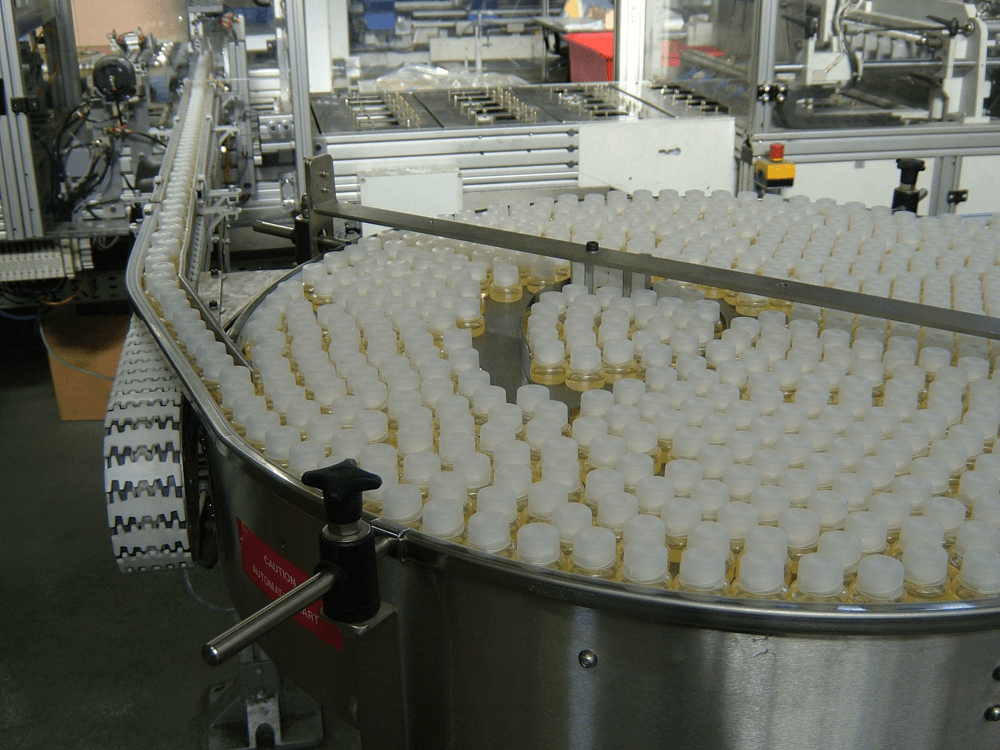

Rotary table systems are usually situated at the beginning or end of a production line. Product can be hand fed or fill by a conveyor where they can be singulated or accumulated on the table, allowing the operators to pack the product or pick and place on to pallets or totes.

Manufactured from Stainless Steel Grade 304, complete with an SEW Eurodrive motor and isolator as standard. We offer the service of cut-outs, product guides and infeed plates, if this is required please contact our team for prices.

A cost-effective way to ensure operators have more time to pack product, and increase the efficiency of the whole production line.