In the fiercely competitive world of bottled products – from the swift churn of dairy processing to the rapid fill of beverage lines, and the precision of pharmaceutical packaging – managing high volumes is a constant challenge. Every second counts, and any interruption to the flow can result in significant losses in productivity and profit. This is precisely where the strategic implementation of Dynamic Diverters becomes a game-changer.

At Asmech Systems Ltd, based in Mansfield, we understand the intricate demands of bottling lines across the UK. We’re seeing how our advanced Dynamic Diverter solution is becoming indispensable for companies in the dairy, beverage, pharmaceutical, and consumer goods sectors, ensuring seamless product rerouting, minimising downtime, and radically enhancing efficiency.

The Bottling Challenge: Speed Meets Specificity

Bottling lines are inherently high-volume operations. Products, often fragile and easily tipped, move at incredible speeds. The challenge intensifies when you need to:

- Handle multiple SKUs: Different bottle sizes, cap types, or labels need to be routed to specific machines.

- Manage fluctuating downstream capacity: If one filler or capper slows down, products need to be redirected instantly.

- Isolate defective products: Faulty bottles must be removed without halting the entire line.

- Optimise line balancing: Ensuring an even flow to multiple packaging machines to prevent bottlenecks.

Manual intervention simply can’t keep up with the pace, leading to jams, errors, and significant slowdowns.

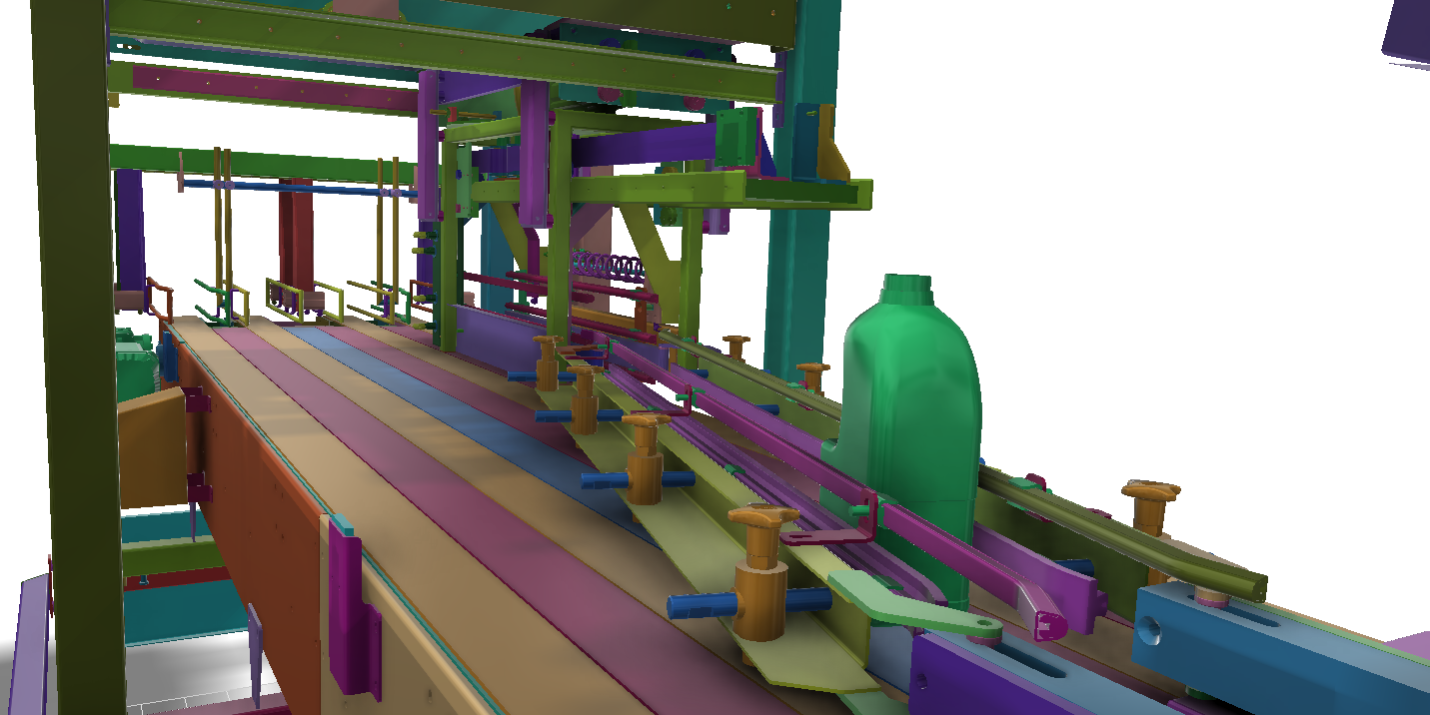

Dynamic Diverters: The Intelligent Traffic Controllers for Bottled Goods

The Dynamic Diverter is an advanced solution tailored for industries handling a variety of bottled goods. It acts as the intelligent traffic controller of your conveyor system, allowing for the smooth, precise, and instantaneous rerouting of products without interrupting the high-speed flow.

Here’s how they provide essential solutions for high-volume bottled product lines:

- Seamless Product Rerouting, On Demand: Imagine producing milk cartons and yogurt pots on the same line, or different soft drink flavours heading to distinct labelling machines. This eliminates the need for manual sorting and allows for continuous production of diverse products.

- Minimising Downtime from Bottlenecks: A jam at a capper or a temporary halt at a filler can quickly bring an entire high-volume bottling line to a standstill. Dynamic Diverters actively monitor the status of downstream equipment. If a machine experiences an issue or reaches capacity, the diverter can automatically reroute incoming bottles to an alternative, available machine, or even to a temporary buffer, preventing the entire line from stopping. This maximises uptime and keeps products flowing.

- Enhancing Efficiency Through Line Balancing: For lines with multiple parallel machines (e.g., several fillers or labellers), a Dynamic Diverter can intelligently distribute the product load evenly. This ensures that no single machine is overwhelmed while others are underutilised, optimising the efficiency of your entire production setup and driving higher overall throughput.

- Precision Handling, Reduced Waste: Bottled products, especially glass, can be fragile. Dynamic Diverters are engineered for gentle and precise handling. They guide products smoothly into their new path, reducing instances of tipping, crushing, or damage, which directly translates to less product waste and improved quality control – vital for industries like dairy and pharma where spoilage or defects are costly.

- Adaptability for Future Growth & Variety: As market demands evolve and you introduce new bottle sizes or product variations, a Dynamic Diverter offers inherent flexibility. Its programmability allows for quick adjustments to routing logic, meaning your line can adapt without major physical reconfigurations, future-proofing your investment.

Asmech: Your Partner in Optimising Bottled Product Handling

At Asmech Systems Ltd., we provide a comprehensive suite of services to ensure your high-volume bottling lines achieve peak efficiency:

- Custom Design & Integration: We don’t offer off-the-shelf solutions. Our expert engineers work closely with you to design Dynamic Diverter systems that are perfectly tailored to your specific bottle types, line speeds, and facility layout, integrating seamlessly with existing conveyors and machinery.

- Precision Manufacturing & Quality: Every Asmech Systems Ltd Dynamic Diverter is built to the highest UK engineering standards, ensuring robustness, reliability, and longevity, even in demanding 24/7 bottling environments.

- Installation, Commissioning & Training: Our skilled teams handle the entire installation process, meticulously commission the system, and provide thorough training for your operators, ensuring a smooth transition and optimal performance from day one.

- Ongoing Support & Maintenance: We offer dedicated after-sales support, including preventative maintenance plans and rapid response services, to keep your Dynamic Diverters operating flawlessly, minimising any potential downtime.

Don’t let inefficient product routing cap your potential. Embrace the power of Dynamic Diverters to streamline your high-volume bottling lines, from dairy to pharmaceuticals and beyond.

Contact Asmech today to discover how our advanced solutions can revolutionise your bottled product handling and boost your bottom line.