In the drive for lean manufacturing, efficiency often takes center stage. Yet, true optimisation goes hand-in-hand with safety. For many UK factories, particularly those handling bottled or packaged goods in sectors like food, beverage, and healthcare, manual product reorientation has long been a hidden ergonomic hazard. This is precisely where the ingenious loop inverter offers a game-changing solution.

A safer workplace is a more productive workplace. At Asmech Systems Ltd., we provide high-quality loop inverters that not only streamline your processes but fundamentally improve ergonomics and reduce the risk of injury on your production lines, working with your operational teams and systems to create a bespoke solution that suits your needs.

The Hidden Risks of Manual Product Orientation

Think about the repetitive actions involved in manually turning, flipping, or reorienting products on a conveyor line:

- Repetitive Strain Injuries (RSIs): Constant twisting, bending, and reaching lead to wear and tear on wrists, shoulders, and backs.

- Awkward Postures: Workers often adopt uncomfortable positions to manipulate products moving at speed.

- Lifting & Dropping Hazards: Even light products, when handled repetitively, can lead to muscle strain or be dropped, causing product damage or foot injuries.

- Fatigue & Errors: Monotonous tasks increase fatigue, leading to a higher risk of mistakes and accidents.

These aren’t just minor inconveniences; they translate into lost time, increased sick leave, higher insurance premiums, and a negative impact on employee morale.

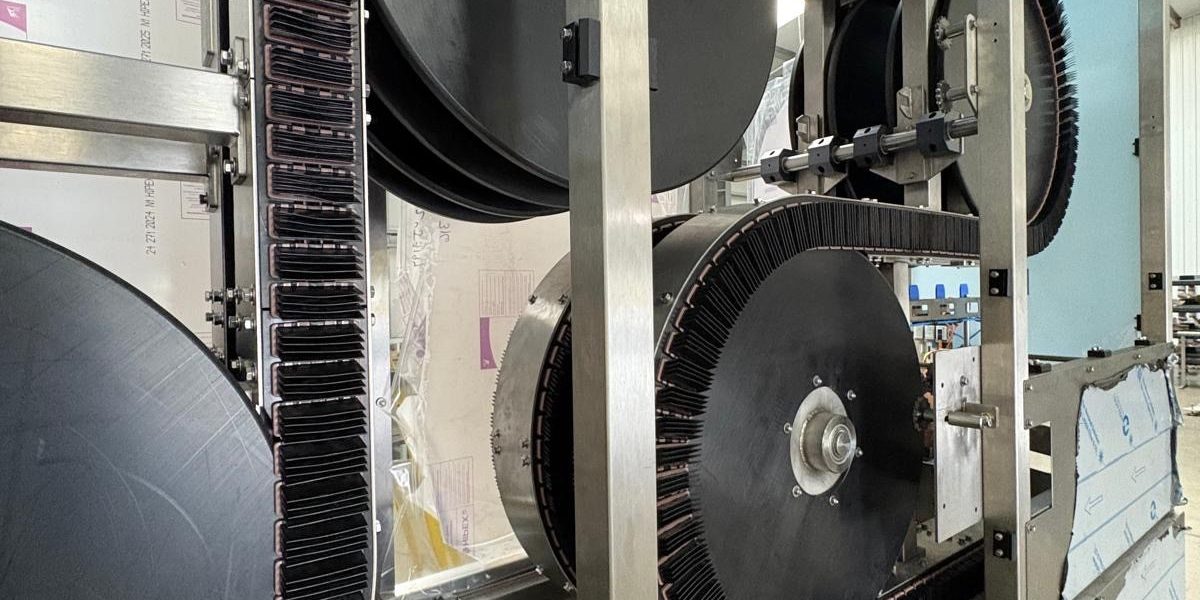

Loop Inverters: A Safety Revolution in Motion

A loop inverter seamlessly reorients products on the fly, within a contained system, eliminating the need for human intervention in this specific task. Here’s how this simple automation delivers significant ergonomic and safety benefits:

- Eliminates Repetitive Manual Handling: This is the primary benefit. By automating the flipping or turning of products, loop inverters completely remove the repetitive motions that are a root cause of RSIs. Workers are freed from monotonous, physically demanding tasks.

- Reduces Awkward Postures and Bending: Since products are reoriented automatically, there’s no need for operators to bend, twist, or reach into uncomfortable positions to correct product alignment. This directly benefits back and joint health.

- Minimises Risk of Drops and Product Damage: The enclosed and controlled nature of a loop inverter ensures products are handled gently and precisely, dramatically reducing the chance of accidental drops that could injure workers or damage valuable products.

- Frees Up Workers for Higher-Value, Safer Tasks: By taking over the physically demanding work, loop inverters allow your skilled workforce to be redeployed to tasks that require cognitive input, problem-solving, quality inspection, or equipment monitoring – roles that are generally less physically taxing and often more engaging.

- Contributes to a Culture of Safety: Investing in automation like loop inverters demonstrates a commitment to employee well-being. This can boost morale, reduce turnover, and foster a more positive and safety-conscious work environment.

Asmech Systems Ltd: Your Partner for Safe and Efficient Automation

At Asmech Systems Ltd, we don’t just provide equipment; we provide solutions that enhance both productivity and safety. Our high-quality loop inverters are engineered for seamless integration into your existing or new production lines in the food, beverage, and healthcare sectors, where hygiene and safety standards are paramount.

Contact us today to speak to one of our experts on 01623 424 442 or at sales@asmechsystems.co.uk