As the days get longer and the sun shines brighter, many industries in the UK gear up for their busiest periods. Whether it’s increased demand for refreshing beverages, a surge in consumer goods, or a heightened need for pharmaceutical supplies, summer often means higher production targets and tighter deadlines. This is precisely where the unsung heroes of the conveyor world – dynamic diverters – step in to ensure your production lines not only cope but truly thrive.

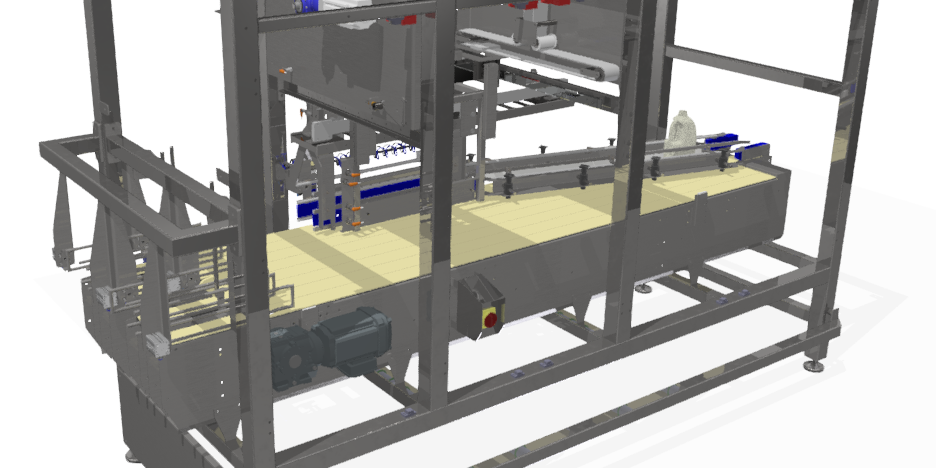

A smooth production flow is paramount, especially during peak seasons. At Asmech Systems Ltd, we’re seeing more and more UK manufacturers leverage the power of dynamic diverters to unlock unprecedented efficiency and maintain quality, even when the heat is on.

What Are Dynamic Diverters and Why Do They Matter?

Imagine your conveyor system as a complex network of roads. A static diverter is like a fixed turn-off – it always sends traffic down the same route. A dynamic diverter, however, is like an intelligent traffic controller. It’s an automated device designed to reroute products smoothly and accurately between different conveyor paths on the fly, without stopping the flow.

This real-time decision-making capability is what makes them indispensable, particularly when production lines face:

- Varying Product Types: Handling multiple SKUs on the same line, requiring different routes for packaging, labelling, or quality control.

- Fluctuating Demand: Needing to direct products to different filling or packing machines based on current output capacities.

- Bottlenecks: Automatically bypassing a temporarily paused machine or overflowing section of the line.

- Quality Control: Rerouting defective products for rejection or further inspection without interrupting the main flow.

Streamlining Summer Production with Dynamic Diverters

Here’s how dynamic diverters act as a game-changer for UK manufacturers tackling summer surges:

- 1. Eliminating Bottlenecks and Maximising Throughput: The most immediate benefit. Dynamic diverters ensure a continuous, uninterrupted flow of products. If one packing machine hits capacity or experiences a brief stoppage, products can be instantly rerouted to an available alternative, preventing costly line stoppages and keeping your overall output at peak levels. This is crucial when demand is high and every minute of uptime counts.

- 2. Enhancing Flexibility for Diverse Product Runs: Summer often brings seasonal products or special promotions. Dynamic diverters allow manufacturers to seamlessly switch between different product types or packaging configurations without manual intervention or time-consuming line reconfigurations. This agility means less downtime for changeovers and more time producing what the market demands.

- 3. Optimising Machine Utilisation: By intelligently distributing products to various downstream machines (e.g., multiple fillers, cappers, or labelling machines), dynamic diverters ensure that no single machine is overwhelmed while others sit idle. This balanced load management maximises the efficiency of your existing equipment, making the most of your capital investment.

- 4. Improving Product Handling and Reducing Damage: Unlike manual rerouting or less sophisticated diverting methods, dynamic diverters are designed for gentle, precise handling. This is especially vital for fragile products like bottled beverages, reducing the risk of breakages, spills, or damage, which translates directly into less waste and higher quality output.

- 5. Boosting Overall Efficiency and Reducing Labour Costs: Automation of routing tasks means fewer manual interventions are required, freeing up your workforce to focus on higher-value activities. This not only cuts down on direct labour costs associated with manual sorting but also improves overall line efficiency.

Asmech: Your Partner for Dynamic Diverter Solutions and More

We pride ourselves on providing bespoke, high-quality conveyor and materials handling solutions tailored to the specific needs of UK manufacturers. Our services linked to dynamic diverters include:

- Expert Consultation & Design: We assess your existing production lines, identify bottlenecks, and design custom dynamic diverter solutions that integrate seamlessly with your current setup.

- Precision Manufacturing: All our dynamic diverters are manufactured to the highest UK engineering standards, ensuring reliability and longevity.

- Seamless Installation & Commissioning: Our skilled engineers ensure a smooth and efficient installation process, minimising disruption to your operations.

- Comprehensive After-Sales Support: We offer ongoing maintenance, spare parts, and technical support to ensure your dynamic diverters perform optimally, year after year.

Don’t let your production lines get jammed as demand heats up this summer. Embrace the intelligence and efficiency of dynamic diverters.

Click here to read about our Dynamic Diverter solutions and case studies about how we’ve supported organisations like yours.

Contact us today on 01623 424 442 or at sales@asmechsystems.co.uk