In the relentless pursuit of optimised production, manufacturers are constantly seeking innovative ways to enhance efficiency, conserve space, and ensure product integrity. While linear conveyor systems are the workhorses of many operations, there are instances where a simple horizontal movement isn’t enough. This is where the often-understated, yet incredibly powerful, loop inverters step into the spotlight.

At Asmech Systems Ltd, we’re keenly aware of the evolving needs of the UK’s vital food, beverage, and healthcare industries. We offer highly effective solutions for our customers, providing quality loop inverters that, when seamlessly integrated with advanced automation systems, unlock a new dimension of benefits.

What is a Loop Inverter?

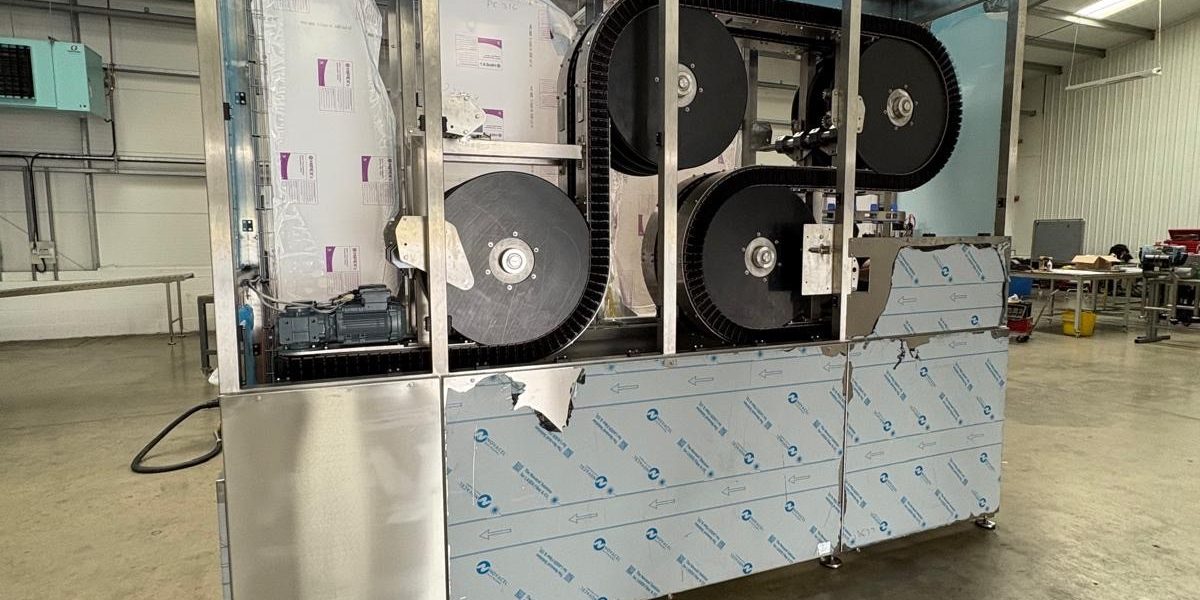

Put simply, a loop inverter is a clever device designed to invert, reorient, or turn over products while they are on a conveyor line, without stopping or handling them manually. Imagine a bottle that needs its base facing up for a particular inspection, or a food tray needing to be flipped for a sealing process. A loop inverter achieves this effortlessly, within a compact footprint.

The Power of Integration: Loop Inverters and Automation Systems

The true transformative power of loop inverters emerges when they are not just standalone units, but integral components of a larger, intelligent automation system. This synergy is particularly beneficial for the food, beverage, and healthcare sectors, where precision, hygiene, and continuous flow are paramount.

Here’s how integrating loop inverters with automation systems delivers significant advantages:

Optimised Product Presentation for Downstream Processes:

- Benefit: Products can be automatically reoriented to the precise position required by subsequent machines (e.g., fillers, cappers, labellers, vision inspection systems). This ensures maximum efficiency for these critical processes, as equipment doesn’t have to compensate for misaligned products.

- Example: A food tray is filled, then inverted by the loop inverter so its bottom can be sealed or dated, ensuring the correct surface is presented to the next automated station.

Enhanced Quality Control & Inspection:

- Benefit: By reorienting products, loop inverters allow automated vision systems to inspect all sides, tops, or bottoms of a product in a single pass. This comprehensive inspection catches defects that might otherwise be missed.

- Example: In pharmaceutical packaging, vials might be inverted to allow cameras to check for fill levels or cap integrity from all angles, ensuring compliance and patient safety.

Space Saving & Compact Line Design:

- Benefit: Loop inverters perform their reorientation function within a surprisingly small footprint, often utilising vertical space or gentle curves. This is crucial for UK factories where floor space is a premium.

- Example: Rather than requiring complex robotic arms that need swing space, a loop inverter achieves the same reorientation in a more compact, efficient manner, freeing up valuable floor space for other operations.

Increased Throughput & Reduced Manual Handling:

- Benefit: By automating the reorientation process, bottlenecks caused by manual flipping or repositioning are eliminated. This maintains a continuous, high-speed flow of products, boosting overall line throughput.

- Example: In beverage lines, bottles needing to be inverted for specific washing or drying stages can be processed without interruption, significantly increasing the number of units per minute.

Improved Hygiene & Product Safety (Especially for Food & Pharma):

- Benefit: Inverting products within an enclosed, automated system minimises human contact, reducing the risk of contamination. For containers that might have debris on the top surface, inversion can help to remove it before further processing.

- Example: A food container might be inverted post-filling to ensure any condensation or residue drips away from the sealing surface before packaging.

What Asmech Offers

At Asmech Systems Ltd, we don’t just sell components; we provide integrated solutions. Our expertise in loop inverters for the food, beverage, and healthcare sectors means we understand the unique demands of hygiene, speed, and precision in these critical industries.

We offer:

- Tailored Solutions: We design and integrate loop inverters that perfectly fit your specific product, line speed, and factory layout.

- High-Quality Engineering: Our loop inverters are robust, reliable, and built to the exacting standards required for demanding 24/7 operations.

- Seamless Integration: We ensure our loop inverters communicate flawlessly with your existing or new automation systems, creating a truly harmonious and efficient production flow.

- Local Support: As a UK-based company in Mansfield, we provide responsive service, installation, and after-sales support right on your doorstep.

Don’t let product orientation be a bottleneck in your production. Embrace the intelligent design and efficiency that integrated loop inverters bring.

Contact Asmech Systems Ltd today to discover how our quality loop inverters can help you unlock new dimensions of productivity and precision on your automated lines.