The dairy industry is a foundation of global food supply, and operates within a complex web of processes, regulations, and ever-evolving consumer demands. From the smooth handling of raw milk to the precise packaging of finished products, efficiency and hygiene are paramount. Within this landscape, Original Equipment Manufacturer (OEM) projects play a vital role, offering specialised equipment and solutions that streamline operations and drive innovation.

Asmech’s approach to OEM

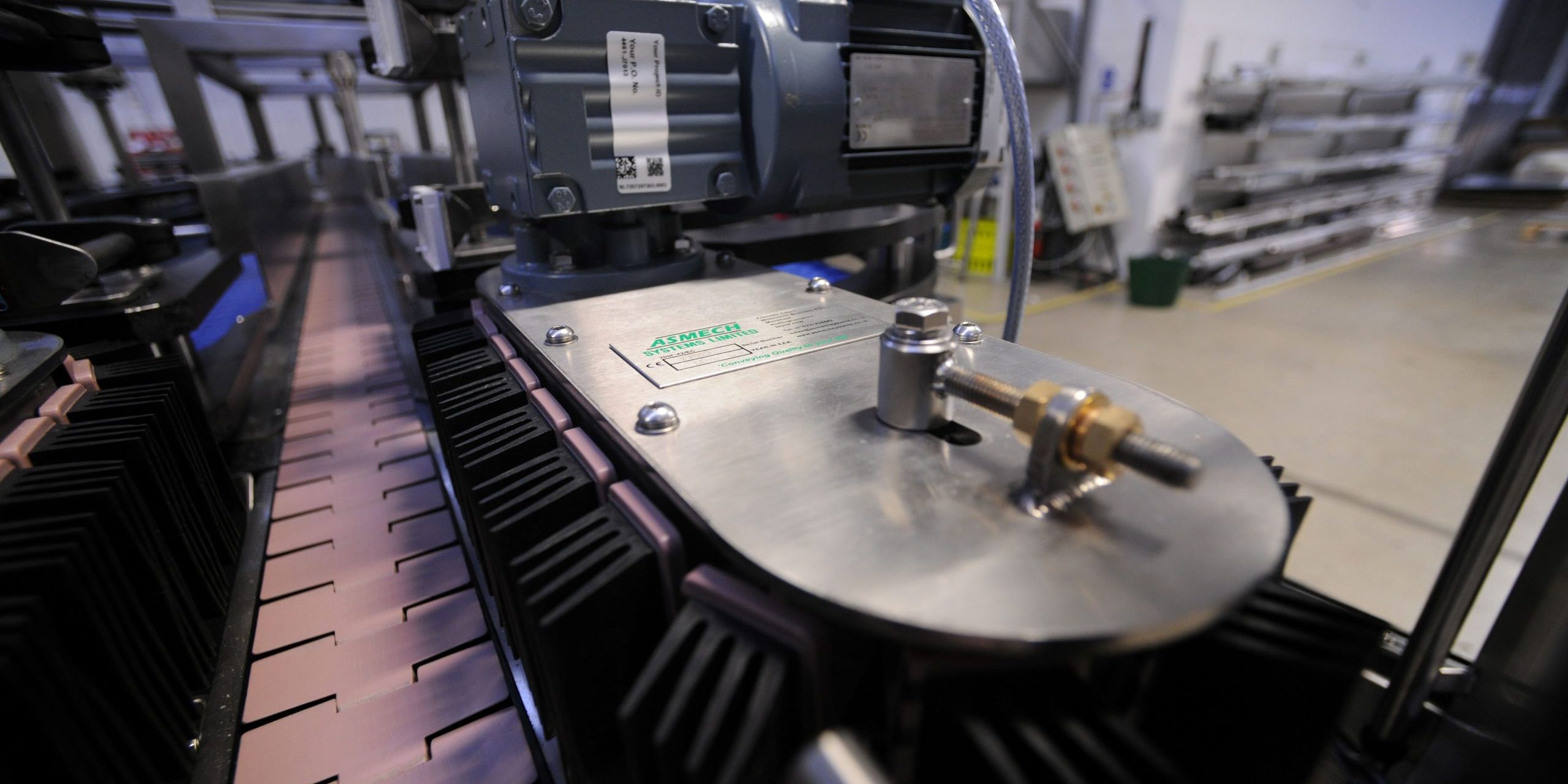

At the core of Asmech Systems Ltd’s approach to OEM projects within the dairy sector, there is a deep understanding of the unique challenges and opportunities our clients face. We recognise that no two dairy operations are exactly the same. The scale of production, the specific types of dairy products manufactured, the existing infrastructure, and future growth aspirations all contribute to a distinct set of requirements. This is where our customer-centric attitude shines.

These diverse needs highlight the limitations of off-the-shelf solutions. Our strength lies in our ability to leverage a comprehensive range of conveying and handling equipment – from robust belt conveyors designed for heavy loads to gentle robotic pick-and-place systems for delicate items – and tailor them precisely to each individual requirement.

Our Variety of Solutions for Your Unique Needs

Our extensive portfolio of equipment forms the building blocks for bespoke OEM solutions. This includes, but is not limited to:

- Belt Conveyors: The workhorses of material handling, offering reliable and efficient transport of various product types and packaging.

- Roller Conveyors: Ideal for accumulating and transporting rigid items like crates and packaged goods.

- Chain Conveyors: Robust solutions for heavier loads and demanding environments.

- Elevators and Lowerators: Facilitating vertical transportation between different processing levels.

- Palletising and Depalletising Systems: Automating the stacking and unstacking of pallets, increasing efficiency and reducing manual labour.

- Robotic Solutions: Offering flexibility and precision for tasks such as picking, packing, and palletising.

This broad range of equipment, together with our engineering expertise, allows us to design and implement solutions that are not just functional, but fully optimised for our clients’ specific operations.

Complete Automated Turnkey Systems

Another place where our capabilities lie is in the design and implementation of complete automated turnkey materials handling systems. We understand that individual pieces of equipment, while important, are only part of the puzzle. The seamless integration of these components into a cohesive and efficient system is what unlocks significant gains in productivity, reduces operational costs, and enhances overall efficiency.

From the initial raw material intake to the final dispatch of finished goods, we can engineer a fully automated flow that minimises manual intervention, reduces the risk of contamination, and ensures consistent product quality. This includes:

- Raw Material Handling: Efficiently conveying and preparing ingredients like milk powder, sugar, and flavourings.

- In-Process Handling: Moving products between different stages of processing, such as pasteurisation, fermentation, and cooling.

- Primary and Secondary Packaging: Automating the filling, sealing, labelling, and packing of individual products and multipacks.

- Palletising and Warehousing: Creating stable and efficient pallet loads for storage and distribution.

From initial concept and design to installation, commissioning, and ongoing support – we provide our clients with a single point of contact and ensure a smooth and successful implementation.

The dairy industry is constantly evolving, and staying ahead requires embracing innovation and efficiency. Contact us today to explore how our customer-centric approach and comprehensive range of OEM solutions can help you optimise your conveying and handling processes and achieve your business goals.