Manufacturing is changing at a pace few could have predicted. Product ranges are expanding, customer expectations are tightening, and the pressure for speed, accuracy, and resilience continues to climb. In this landscape, the conveying system – often the backbone of any material handling operation – must evolve just as quickly.

A conveyor that was installed to solve yesterday’s challenges may not be equipped for tomorrow’s demands. That’s why forward-thinking manufacturers are now looking for ways to future-proof their conveying systems and protect their productivity in a rapidly shifting environment.

Designing for Flexibility Through Modular Conveying Systems

Modern manufacturing environments demand flexibility. Product lines change, packaging updates frequently, and businesses need to scale production up or down without major disruption. A future-ready conveying system is one built on modularity. These systems allow manufacturers to reconfigure, extend, or upgrade sections as needs evolve, making it possible to adapt without full system replacement. This adaptability has become one of the most valued characteristics in contemporary conveyor design.

At the same time, automation is no longer something to plan for “one day.” From robotic palletisers to vision-guided quality checks, automation is becoming deeply integrated into material handling workflows. Conveyors need to be automation-ready with smart control systems, sensor capability, and integration points for robotics and connected machinery. Even if a facility isn’t fully automated yet, having a conveyor system designed for easy integration ensures smooth growth later – not expensive retrofits.

Improving Efficiency with Energy-Smart Conveying Technology

Energy efficiency is another central concern as manufacturers face rising utility costs and stricter sustainability goals. Modern conveying technology offers considerable gains through high-efficiency motors, low-friction components, and intelligent start/stop systems that reduce unnecessary energy consumption. For many facilities, the shift to energy-efficient conveying systems delivers immediate ROI while supporting long-term environmental targets.

The ability to stay online is equally crucial. Unplanned downtime is consistently one of the most damaging factors in production output. This is why predictive maintenance is becoming a defining feature of future-proof material handling. Conveyors equipped with condition monitoring and smart alerts help engineers catch issues before they escalate – keeping throughput steady and extending equipment lifespan. As more manufacturers adopt data-driven operations, this level of insight is becoming essential.

And of course, safety remains a priority. As production speeds increase and automation becomes more common, ensuring the conveying system is compliant, intuitive, and operator-friendly is vital. Future-proofing here means designing with advanced guarding, reliable emergency stop systems, and ergonomic features that reduce operator fatigue.

Ultimately, a future-proof conveying system is one that protects the business from disruption. It gives manufacturers confidence that their production line can handle whatever comes next – whether that’s new product introductions, increased demand, workforce shortages, or the adoption of new automation technologies.

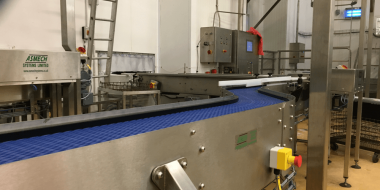

At Asmech Systems Ltd, we’re helping UK manufacturers design and upgrade conveying systems that not only solve today’s material handling challenges but anticipate the many of tomorrow. With a focus on modular design, automation readiness, energy efficiency, and long-term flexibility, we ensure your conveying system remains an asset that grows with your business – not one that holds it back. Contact us today on 01623 424 442 or at sales@asmechsystems.co.uk